Lindapter Girder Clamps provided a solution for securing a production riser.

Location: Central North Sea

Product: Type AF Girder Clamp

Market: Oil & Gas - Offshore

Client: Apache North Sea Ltd

Aviat is a shallow gas field located in Block 22/7A of the North Sea which is being developed by Apache. The gas field will provide a reliable cost effective source of fuel to the Forties Alpha platform, in order to support maximisation of its production and maintain low operating costs, through to end of field life beyond 2030.

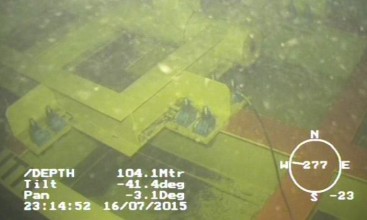

Apache’s structural design engineers were tasked with finding a robust connection to secure a production riser to the base support frame which would be more than 330ft below sea-level. The connection needed to withstand high loads and outlive the production riser, while providing a quick way for the divers to install when wearing thick gloves underwater.

Corrosion resistance and fatigue life were important as the connection needed to be able to support high loads and deal with wave action for over 15 years.

Various conventional connections were evaluated and some were immediately rejected because the exact position of the joint was unknown whereas the adjustable Lindapter clamping systems prevented this from being a problem.

The Apache engineers contacted Lindapter’s technical team and took advantage of the free connectiondesign service. They quickly received a connection detail drawing proposing heavy duty 1” Type AF Girder Clamps, which are manufactured from SG iron with a hot dip galvanized coating as standard.

During installation, the subsea diving engineers benefited from the lateral adjustability of the Type AF which allowed the framework to be quickly positioned and tightened using just simple hand tools. The divers found installing the girder clamps quick and easy even with thick gloves underwater.

Lindapter Type AF Girder Clamps provided the tensile and slip resistance that was required for the loads anticipated during the life of the production riser.

The solution simplified the design issues, installation process and operational activities for improvements in long term reliability, such as a reduced need for inspection and maintenance. The guaranteed safe working loads and superior corrosion resistance both contributed to a successful subsea installation.

- High slip resistance for tensile & frictional loads

- Fully adjustable onsite for easy installation

- No drilling or welding required

- Hot Dipped Galvanized finish offers a cost effective and low maintenance solution

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.