Lindapter Girder Clamps provided a solution for securing steel framework to support heavy duty pipes.

Location: Selby, North Yorkshire, UK

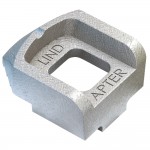

Product: Type AF & Type A Girder Clamps

Market: Power Generation (other)

Client: REG Bio-Power

Whitemoor Power Station, located near Selby in North Yorkshire, has the capacity to provide 18 megawatts of electricity to the UK National Grid. The power plant is one of REG Bio-Power’s fleet of renewable energy generating stations in the UK and uses waste cooking oil to create a bioliquid, which is then burnt to produce eco-friendly energy.

During the construction of the power plant engineers needed a safe and secure method of connecting steel sections together to create pipe support structures that would carry heavy duty pipelines around the plant. Engineers required the supports to be adjustable to allow for pipe installation tolerances, this was particularly important at critical locations such as pipeline joints. Another consideration was the protective galvanized coating of the pipes which needed to remain undamaged during installation. This, along with Health & Safety considerations, ruled out welding as an option.

Lindapter worked with the engineer to design several simple but effective connections using a variety of Lindapter Girder Clamps, each clamp optimized to suit the required application. Type AF high slip resistance girder clamps in a four-bolt connection were specified for both tensile and frictional connections of the heavy duty pipes to the support structures. Type A girder clamps were used for tensile connections of smaller, lighter duty pipes.

The adjustability of the girder clamps allowed the contractor to slide and align the steel sections of the support structure into the exact positions required, before the clamps were tightened with hand tools. Brackets around the pipes were then connected to the support structure using a Girder Clamp connection. Again, the adjustability gave the contractor flexibility to overcome any alignment issues in the field.

Lindapter girder clamps provided a drilling and weld free connection that prevented any damage to the galvanized coating of the pipes. The contractor found the process of aligning the support structure and pipe brackets quick and easy due to the adjustability of the clamps. The girder clamps have independent technical accreditations, including the CE mark (ETA-13/0300), TÜV and Lloyd’s Register approvals and in addition the Type AF has ICC-ES approval. These accreditations verify the load and slip capacities that led to a safe installation.

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.