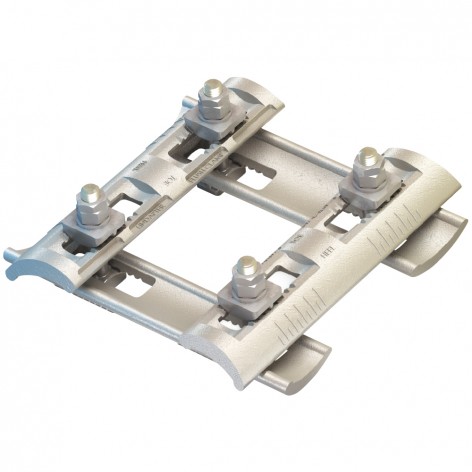

Type FC Girder Clamp

All-in-one full connection clamp device used to connect steel sections with flat or tapered flanges and to resist moderate tensile loading.

Overview

The Type FC girder clamp is a full connection system that adjusts to fit a variety of beam types with flat or tapered flanges up to and including 10°. It is supplied as a pre-configured assembly that does not require a location plate and is ready for installation ‘out of the box’. Capable of resisting moderate tensile loadings or low slip loadings. Can be used to connect beams that are positioned at angles between 45° and 90° depending on beam flange widths. Manufactured from forged steel with zinc plated and JS500 finish to provide high performance and anti-corrosion protection.

Features & Benefits

- 'All-in-one' device for connecting steel sections.

- Adjustable to suit both beam width and flange thicknesses.

- Quick and easy to install.

- For parallel and tapered flanges up to and including 10°.

- No location plate required.

Properties

- Manufactured from forged steel to BS EN 1562.

- Available with zinc plated JS500 finish.

- Reaction to fire: A1 (Steel)

Durability and corrosion protection:

| Corrosivity Class | Electroplated Steel with JS500 |

| C1 | More than 50 years |

| C2 | More than 20 years |

| C3 | More than 10 years |

For C4 and C5 corrosion categories contact us.

Technical Specification

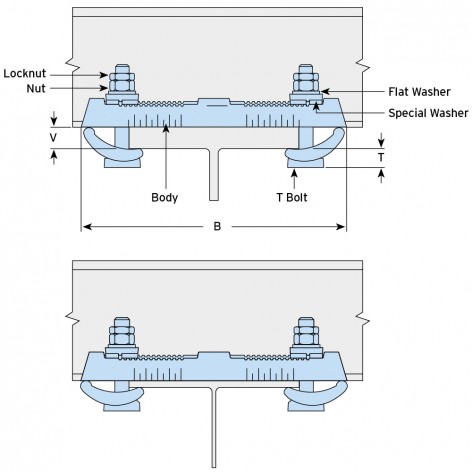

| Safe Working Loads (FOS 5:1) | Clamping Range | Dimensions | ||||||

|---|---|---|---|---|---|---|---|---|

| Product Code | T Bolt 8.8 | Tensile / 4 Bolts | Slip / 4 Bolts | Tightening Torque* | Flange Thickness V | Flange Width1) | T | B |

| kN | kN | Nm | mm | mm | mm | mm | ||

| LFCM16 | M16 | 30.0 | 7.5 | 147 | 5 - 19 | 75 - 180 | 22 - 27 | 304 |

1) Depending on beam connection angles. Download the datasheet for more information.

* Torque figures based on bolts / setscrews in an unlubricated condition.

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.012

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.012

| Safe Working Loads (FOS 5:1) | Clamping Range | Dimensions | ||||||

|---|---|---|---|---|---|---|---|---|

| Product Code | Special Bolt Size Z | Tensile Resistance / 4 Bolts | Slip Resistance / 4 Bolts | Tightening Torque* | Flange Thickness V | Flange Width1) | T | B |

| lbs | lbs | ft lb | ||||||

| LFCM16 | M16 (5⁄8") | 6744 | 1686 | 108 | 3⁄16" - 3⁄4" | 3" - 7" | 7⁄8" - 11⁄16" | 12" |

1) Depending on beam connection angles. Download the datasheet for more information.

* Torque figures based on fasteners in an unlubricated condition.

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.