Lindapter Girder Clamps provided a solution for the installation of large platform canopies.

Location: Mülheim, Germany

Market: Rail

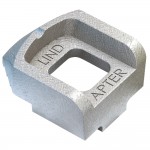

Product: Type A & B Girder Clamps

Client: Deutsche Bahn AG

Deutsche Bahn AG is the largest railway operator and infrastructure owner in Europe and carries around two billion passengers on the German rail network annually. As part of their continued railway infrastructure investment programme in the North Rhine-Westphalia state Deutsche Bahn are modernizing 150 stations by 2023.

Mülheim (Ruhr) Styrum railway station was identified by Deutsche Bahn as requiring work, in particular the two central platforms needed modernizing. The proposed work included, redeveloping the platforms and raising them to achieve a step-free transition onto to trains, plus the installation of new canopies to protect passengers from inclement weather.

One of the challenges the contractor faced was how to secure steel beams to the loadbearing columns to construct a frame for the canopies to be fixed to without drilling or welding in the field.

After researching and evaluating several connection methods, the CE approved Type A & B Girder Clamps by Lindapter were specified due to their high load capacity and range of independent approvals.

Engineers designed a four-bolt connection with location plate, that didn’t require field drilling or welding, to connect steel beams to the extended arms of the columns.

The design provided a suitable structure for fixing the canopy panels to, and for a high degree of corrosion protection a hot dip galvanized (HDG) finish was specified on the Girder Clamps.

After the loadbearing steel columns were installed along the length of the platforms, steel beams were lowered into position on top of the extended arms. The steel beams, which spanned from one column to the next, were connected using the location plate and four-bolt configuration consisting of Lindapter Type A & B clamps.

Installation was quick and easy as each bolt was simply inserted into the pre-drilled holes with the Type A holding the bolt captive while the nut on the Type B clamp was tightened with a torque wrench. To complete the installation the canopy panels were fixed to the steel beams.

Lindapter Type A & B Girder Clamps provided a drilling and weld free connection in the field that was quick and easy to install. The clamps are fully adjustable which gave the contractor the ability during installation to manoeuvre the beams into their final positions before fully tightening them. Redevelopment of the platforms were successfully completed on time and now provide a modern, safe and comfortable environment for passengers. Deutsche Bahn have since specified the same connection design on many other platforms throughout the country.

- Fully adjustable onsite for easy installation

- No drilling or welding required

- Hot Dip Galvanized finish offers a cost-effective and low maintenance solution

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2024. All rights reserved.