Lindapter Girder Clamps provided a solution for connecting a huge LED media board to an iconic 100 foot high Second World War bunker.

Location: Pragsattel, Stuttgart, Germany

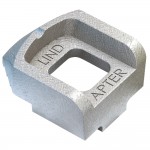

Product: Type AAF & Type A Girder Clamp

Client: Lotus Media

Contractor: LEDCON Systems GmbH

Engineer: Ingenieurbüro Brandt GmbH

This iconic 100 foot high Second World War bunker is located on a major traffic junction enroute to Stuttgart, known as Pragsattel. Due to its prominent position the bunker has been used as an advertising medium since shortly after the Second World War. In the 1990’s a video wall was installed and in 2008 upgraded with a then state-of-the-art screen.

In 2023 Lotus Media, the company operating the screen, decided the time was right to replace the entire advertising system with the very latest LED screen technology. They wanted to increase the size and resolution of the screen, reduce energy costs by using LED technology while protecting and retaining as much of the original structure as possible. To meet these requirements Lotus commissioned LED specialists LEDCON as the full service contractor for the project.

The LEDCON solution involved attaching a secondary steel frame to the existing frame on the outside of the bunker, as part of this secondary frame special plate brackets were designed. The plate brackets were pre-drilled during fabrication so that once in the field the installers could firstly bolt them to the secondary frame and then pre-assemble the girder clamps to the plate brackets prior to each section of the secondary frame being hoisted up the bunker. The secondary frame would then be connected to the existing frame via the plate brackets using a combination of Lindapter Type AAF and Type A girder clamps in a 2-bolt configuration. The LED screens would then be attached to the secondary frame using the method specified by the screen manufacturer.

To begin with the old system weighing 4.5 tons had to be dismantled piece by piece this included the old display screens and sections of the support frame. At ground level the plate brackets were bolted to the new sections of the secondary frame and then the girder clamps pre-installed. Each section of the secondary frame was then carefully hoisted up the bunker until they were close to where they were needed, installers then tightened the Lindapter clamps on the plate brackets to the existing frame on the bunker. Once final adjustments were made and the sections of frame were in the correct positions, installers fully tightened the clamps with a calibrated torque wrench. To complete the installation the new LED screens were attached to the secondary frame.

The Lindapter solution provided a fast, safe installation and avoided costly field drilling or welding that would have been difficult to carry out at this height. The Lindapter girder clamps were able to provide the necessary loads given by the new screen which weighed a total of 2.6 tons. The adjustability of the clamps also allowed the frame to be accurately installed which would have been very difficult with permanent welds. The new LED screen is now 22% larger than the previous screen and is 70% more energy efficient.

- No field welding or drilling

- Quick and easy installation

- Adjustable for precise alignment

- Safer solution

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.