Lindapter Girder Clamps provided an adjustable solution for securing overhead line equipment and electrification catenary systems.

Location: Johannesburg to Pretoria, Gauteng, South Africa

Market: Overhead Line Equipment

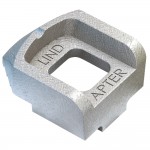

Product: Type A Girder Clamps

Client: Gauteng Provincial Government

Contractor: Tractionel Enterprise

The Gautrain High Speed Rail project was the subject of extensive planning in the late 1990s to produce designs for a north-south and east-west rail route serving the Gauteng Province. Construction of the largest railway project in Africa at the time started in 2006 and was part of the government’s plan to improve infrastructure and travel in time for the 2010 FIFA World Cup.

Railway electrification specialists Tractionel Enterprise won the contract to design, supply and install the overhead contact distribution system (OCDS) to 80 kilometres of track. The overhead design incorporated many different steel profiles, varying in both shape and thickness, to which overhead line equipment (OLE) and electrification catenary systems needed to be connected. The client wanted a connection solution that was easy to handle, interchangeable, fool proof, robust and cost effective.

Lindapter were approached by the contractor to offer an alternative solution to the traditional method of using bolts, nuts and back straps. The Lindapter technical support team designed a series of simple connection details using Lindapter Type A Girder Clamps to secure cantilevered arms to the steel columns that ran the entire length of the track. The primary solution was a beam end plate to column design using Type A girder clamps in a four-bolt configuration. This provided the necessary strength to support the cantilevered arms over the track so that overhead line equipment and electrification catenary systems could be installed.

Installation was quick and easy as each bolt was simply inserted into predrilled holes in the end plate of the cantilevered arms with the Type A on one end and nut on the other. The adjustability of the girder clamps allowed the contractor to align the cantilevered arms into the exact positions required. To complete the connection the recessed top of the clamp held the bolt captive while the nut was tightened with hand tools to the recommended tightening torque.

A total of 16,000 Type A girder clamps were used to provide a faster and simpler to install connection versus the traditional method of bolts, nuts and back straps. The lightweight clamps were easy to handle and were supplied with a hot dipped galvanized finish offering a cost effective, robust and low maintenance solution. The railway opened in June 2010, in time for the 2010 FIFA World Cup, and runs for 80 kilometres across open routes, viaducts and tunnels linking Johannesburg to Pretoria.

“Lindapter supplied a cost-effective solution to each of the interfaces, off the shelf, supported by a very professional technical support team. The Gautrain design relies heavily upon the quality of the steel component interfaces to achieve the final system requirements – and this was achieved by utilising the ingenious Lindapter designs.” Allan Macpherson, Tractionel Enterprise

- Fast cost-effective installation

- Only hand tools required

- No need for specialist labor

- Corrosion resistant hot dipped galvanized finish

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2024. All rights reserved.