Lindapter Girder Clamps provided an ICC-ES approved solution for connecting seismic bracing cables to the primary steel of this electric vehicle battery plant cleanrooms.

Location: Stanton, Tennessee, USA

Seismic Design Category: "D" High Hazard

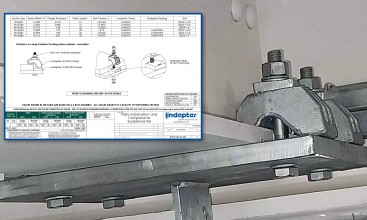

Product: Type AAF Girder Clamps

Quantity: 2,000

Client: Ford

The BlueOval City in Stanton, Tennessee, is a significant part of Ford’s push towards electric vehicles. This massive campus will include a state-of-the-art battery plant, known as the BlueOval SK Battery Plant, which is set to begin production in late 2025.

This facility is part of Ford’s broader strategy to lead the electric vehicle revolution and create a sustainable manufacturing ecosystem in the United States.

BlueOval City is close to the New Madrid seismic zone and is in Seismic Design Category (SDC) D meaning there is a hazard from very strong shaking in the event of an earthquake.

Due to being in SDC D the engineer was proposing heavy duty diagonal seismic bracing cables made of ½” diameter 6x19 steel wire rope to connect the suspended ceiling to the primary beams and to restrain pipe racks.

Ford stipulated that they did not want any permanent connections to the primary steel to future proof the plant should they want to reconfigure it in the future, so the engineer contacted Lindapter and inquired about a clamping solution that would be approved and compliant for seismic designs.

The engineer provided Lindapter’s technical support team with the loads and locations of where the seismic cable braces were to be installed along with the cable brace forces that had to be resisted. The lateral force that needed to be resisted was substantial at 5973 lbs for each cable brace, with one brace installed every 4ft throughout the plant.

From the information supplied Lindapter’s technical support team was able to propose a solution that was ICC-ES approved for use in Seismic Design Category D. The design consisted of an end plate with a fabricated gusset plate welded to it with two pre-drilled holes. The end plate was to be connected to the primary steel beams of the building with Lindapter Type AAF adjustable high slip resistance girder clamps (size ½” and ¾”) in a 4-bolt configuration. The seismic bracing cables would then attach to the holes in the gusset.

Lindapter’s solution enabled the quick installation throughout the plant and overcame the challenge of connecting to six different thicknesses of wide flange beams varying from W14x90 up to W14x283. For the beams with thicker flanges such as the W14x283 that has a flange around 2” thick the girder clamp connection design also included packing pieces to increase the clamping range of the girder clamps. In total the contractor used 2,000 Type AAF Girder Clamps to connect the end plates to the primary beams. Installation was quick and easy as the connection assemblies could be positioned close to where they were needed before final adjustments

were made and the clamps fully tightened.

Lindapter Type AAF heavy duty girder clamps provided an SDC D approved solution compliant with ICC-ES report ESR-3976. They also provided sufficient strength to resist the high loads that would be present in an event of an earthquake. Installation was quick and easy with no field drilling or welding so no damage was caused to the primary steel. Lindapter’s technical solution met the client’s key requirement of a code-compliant, seismic resistant connection that can be removed for future reconfiguration of this world-class manufacturing facility.

- ICC-ES seismic approved solution

- Heavy duty, high load capacities

- No drilling or welding required

- Removeable for adaptability

- Fully adjustable in the field

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.