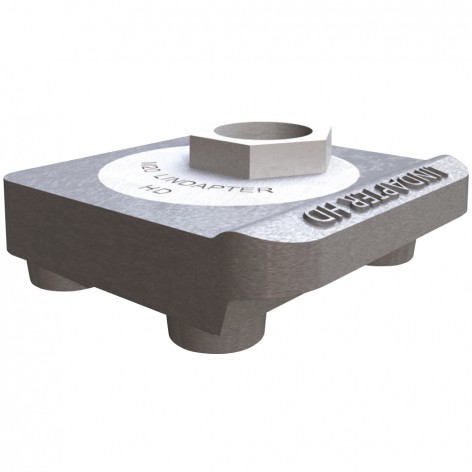

Type HD Rail Clamp

High strength clamp for low speed rail applications. Provides lateral adjustability for fast and precise rail alignment.

Overview

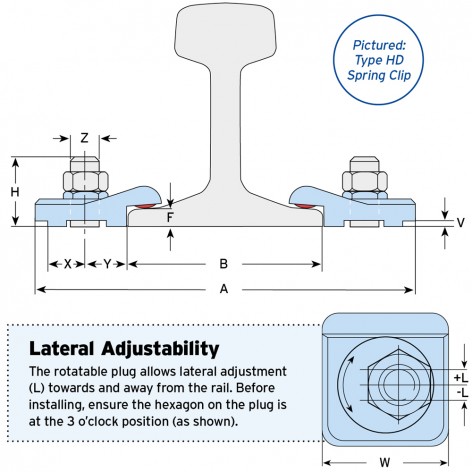

The Type HD is used to secure sections of rail or crane lines in low speed applications, up to 60 metres per minute, such as ground track, elevated rail and overhead gantries. The rail clip features a rotatable central component that provides a high degree of lateral adjustability. It allows contractors to quickly and precisely align rails before securing them in position using standard hand tools. The clamps are manufactured from high strength SG iron, creating a reliable connection that minimises maintenance requirements.

The clips are used in a variety of environments including train maintenance depots, industrial facilities, water treatment plants, dam/dockside cranes, automated warehouses and power stations. Four product variants are available, each in sizes M20 or M24 to meet the diverse requirements of each industry and application (see product options below for more details).

Product Options

Type HD Soft

This clip does not touch the top of the rail, which allows the rail to lift slightly to accommodate rail wave, reducing stress and fatigue in the rail and clips.

Type HD Hard

Designed to hold the rail down tightly to prevent rail uplift. Like other Type HD rail clips, it is made from high strength SG iron.

Type HD Spring

An elastomer spring provides vertical restraint while still allowing the rail to lift with rail wave. It also reduces track running noise.

Type HD Isolated

For rail applications requiring electrical isolation, this product features a nylon insulator (also known as British Rail Orange).

For product comparison chart download datasheet.

Features & Benefits

- High strength clamp.

- Suitable for all rails with tapered flanges and crane speeds up to 60m/min.

- High degree of lateral adjustability.

- No rail damage as drilling or welding the rails is not required.

- Safely and easily secures rail using only hand tools.

- Four options available for various requirements.

- Overcomes issues with misalignment of studs.

- Contact Lindapter for wheel loads above 400kN or lateral loads higher than wheel loads.

- Please contact Lindapter to ensure suitability of component for application.

Properties

- Manufactured from SG iron to BS EN 1563.

- Available with zinc plated, hot dip galvanised or sheraplex finish if required.

Technical Specification

| Normal Lateral Conditions | High Lateral Conditions | Dimensions | Distances1) | Width | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clip Type | Product Code | Bolt 8.8 | SWL (FOS 4:1) | Tightening Torque* | SWL (FOS 4:1) | Tightening Torque* | Leg Length3) | Stud Length3) | Lateral Adjustment | Plate Width | Y | X | W |

| Z | V | H | L | min. A | |||||||||

| kN | Nm | kN | Nm | mm | mm | mm | mm | mm | mm | mm | |||

| Soft | HD20S | M20 | 22.5 | 185 | 46.0 | 450 | F - 4 | F + 40 | +/- 11.5 | B + 137 | 30 | 27 | 74 |

| Soft | HD24S | M24 | 40.0 | 320 | 60.0 | 760 | F - 4 | F + 43 | +/- 8 | B + 130 | 30 | 27 | 74 |

| Hard | HD20H2) | M20 | 22.5 | 185 | 46.0 | 450 | F - 8 | F + 38 | +/- 11.5 | B + 137 | 30 | 27 | 74 |

| Hard | HD24H2) | M24 | 40.0 | 320 | 60.0 | 760 | F - 8 | F + 41 | +/- 8 | B + 130 | 30 | 27 | 74 |

| Spring | HD20SP | M20 | 22.5 | 185 | 46.0 | 450 | F - 7 | F + 40 | +/- 11.5 | B + 137 | 30 | 27 | 74 |

| Spring | HD24SP | M24 | 40.0 | 320 | 60.0 | 760 | F - 7 | F + 43 | +/- 8 | B + 130 | 30 | 27 | 74 |

| Isolated | HD20SPOR | M20 | 22.5 | 185 | 46.0 | 450 | F - 6 | F + 42 | +/- 11.5 | B + 147 | 35 | 27 | 74 |

| Isolated | HD24SPOR | M24 | 40.0 | 320 | 60.0 | 760 | F - 6 | F + 45 | +/- 8 | B + 140 | 35 | 27 | 74 |

1) Based on plug set at 3 o’clock position.

2) Not suitable for use with a resilient pad.

3) Please specify the required leg length (V) when ordering. If you are using the resilient pad with Soft, Spring or Isolated types (resilient pads are not suitable with Hard), increase the leg length and stud length (H) by the thickness of the pad.

* Torque figures based on bolts / setscrews in an unlubricated condition.

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.