Type HB Hollo-Bolt™ Hexagonal Head

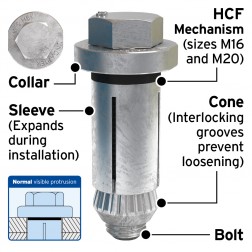

Hollo-Bolt Hexagonal Head is an expansion bolt that only requires access from one side of the Structural Hollow Section (SHS).

Overview

Hollo-Bolt expansion bolts require access to only one side of the Structural Hollow Section (SHS), and offer a faster alternative to welding or through-bolting, enabling contractors to reduce construction time and labour costs. Installation is quickly carried out by inserting into pre-drilled steelwork and tightening with a torque wrench. Also suitable for blind connections where access is available from one side only.

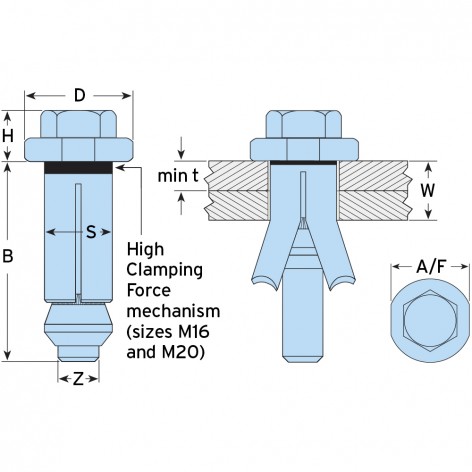

The larger M16 and M20 Hollo-Bolts are optimised for high strength structural connections and feature a unique High Clamping Force (HCF) mechanism for superior performance.

NEW Carbon steel, hexagonal head Hollo-Bolts in all sizes have been independently fire tested in both tension and shear in accordance with ISO 834 and are fire rated up to 120 minutes. For further details and load data please contact Lindapter.

Features & Benefits

- Fast, cost saving installation from one side.

- For square, rectangular and circular hollow sections.

- High resistance to shear and tension.

- Unique High Clamping Force design (size M16 & M20).

- Low temperature tested to -45°C (carbon steel variants).

- Other head types available.

- Independently tested for dynamic load applications to EN 1993-1-9. Contact us for more details.

- NEW Independently fire tested to ISO 834*

- Hollo-Bolt plug-in tool available to download within Tekla Warehouse.

- Watch the Hollo-Bolt removal videos here www.lindapter.com/hollo-bolt-faqs

Properties

- Manufactured from mild steel or stainless steel grade 316.

- Available with zinc plated, hot dip galvanised or sheraplex finish.

- Reaction to fire: A1 (Steel)

Durability and corrosion protection:

| Corrosivity Class | Galvanised Steel | Electroplated Steel | Sheraplex | Stainless Steel |

| C1 | More than 50 years | More than 50 years | More than 50 years | More than 50 years |

| C2 | More than 50 years | More than 20 years | More than 50 years | More than 50 years |

| C3 | More than 20 years | More than 10 years | More than 20 years | More than 50 years |

For C4 and C5 corrosion categories contact us.

Technical Specification

| Collar | Safe Working Loads (5:1 Factor of Safety) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Code | Bolt Ø | Height | Length | Clamping Thickness | Outer Ply | Sleeve Outer Ø | Ø | Tightening Torque | Tensile | Single Shear | |

| Z | H | B (max) | W | min t | S | D | A/F | ||||

| mm | mm | mm | mm | mm | mm | mm | Nm | kN | kN | ||

| HB08-1 | M8 | 10.5 | 45 | 3 - 22 | - | 13.75 | 22 | 19 | 23 | 4.0 | 5.0 |

| HB08-2 | M8 | 10.5 | 65 | 22 - 41 | - | 13.75 | 22 | 19 | 23 | 4.0 | 5.0 |

| HB08-3 | M8 | 10.5 | 85 | 41 - 60 | - | 13.75 | 22 | 19 | 23 | 4.0 | 5.0 |

| HB10-1 | M10 | 12.5 | 49 | 3 - 22 | - | 17.75 | 29 | 24 | 45 | 8.5 | 10.0 |

| HB10-2 | M10 | 12.5 | 64 | 22 - 41 | - | 17.75 | 29 | 24 | 45 | 8.5 | 10.0 |

| HB10-3 | M10 | 12.5 | 84 | 41 - 60 | - | 17.75 | 29 | 24 | 45 | 8.5 | 10.0 |

| HB12-1 | M12 | 14.5 | 53 | 3 - 25 | - | 19.75 | 32 | 30 | 80 | 10.5 | 15.0 |

| HB12-2 | M12 | 14.5 | 73 | 25 - 47 | - | 19.75 | 32 | 30 | 80 | 10.5 | 15.0 |

| HB12-3 | M12 | 14.5 | 93 | 47 - 69 | - | 19.75 | 32 | 30 | 80 | 10.5 | 15.0 |

| High Clamping Force | |||||||||||

| HB16-1 | M16 | 18 | 67 | 12 - 29 | 8 | 25.75 | 38 | 36 | 190 | 21.0 | 30.0 |

| HB16-2 | M16 | 18 | 92 | 29 - 50 | 8 | 25.75 | 38 | 36 | 190 | 21.0 | 30.0 |

| HB16-3 | M16 | 18 | 112 | 50 - 71 | 8 | 25.75 | 38 | 36 | 190 | 21.0 | 30.0 |

| HB20-1 | M20 | 22.5 | 80 | 12 - 34 | 8 | 32.75 | 51 | 46 | 300 | 35.0 | 40.0 |

| HB20-2 | M20 | 22.5 | 110 | 34 - 60 | 8 | 32.75 | 51 | 46 | 300 | 35.0 | 40.0 |

| HB20-3 | M20 | 22.5 | 140 | 60 - 86 | 8 | 32.75 | 51 | 46 | 300 | 35.0 | 40.0 |

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoC No.101

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoC No.101

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.001

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.001

• Hollo-Bolts can be used on a wide variety of steel hollow shape sections. Safe working loads shown are applicable to the Hollo-Bolt only in both tension and shear. Failure of the section could occur at a lower figure and its strength should be checked by a qualified Structural Engineer.

• Independently tested for dynamic load applications to EN 1993-1-9.

* Carbon steel, hexagonal head Hollo-Bolts in all sizes. For further details and load data please contact Lindapter.

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2025. All rights reserved.