Lindapter Hollo-Bolts provided a solution for connecting large electrical conductors to the base of the observation wheel.

Location: Dubai, United Arab Emirates

Market: Arts / Entertainment / Staging

Product: Hollo-Bolt by Lindapter

Client: Paul Vahle GmbH & Co. KG

The Vahle Group is a specialist high-tech designer and manufacturer of products and systems including electrical conductor rails. For over four years Vahle worked on the tender for the Ain Dubai (Dubai Eye) providing technical and commercial details. The Vahle system was to provide electrical power to the 48 luxury air conditioned passenger cabins and 65,000 decorative LEDs on the Ain Dubai which would be the world’s largest observation wheel at over 250 metres tall.

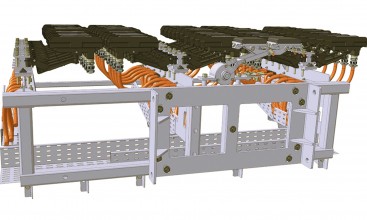

Two steel framed units carrying the electrical conductors and measuring 1.8m x 1.1m had to be attached to either side of the observation wheel and secured to the steel base frame. The conductor units were manufactured using Structural Hollow Section (SHS) and so the client needed a simple but secure solution for connecting them to the base whilst also providing a small degree of adjustability on site.

Lindapter’s technical support team worked with the client in order to design a suitable connection using Hollo-Bolt, the original expansion bolt for Structural Steel that requires access to only one side of the SHS. The design incorporated a series of slotted holes in the base frame which the Hollo-Bolt could be inserted through and into pre-drilled holes in the SHS of the conductor unit frame. Hollo-Bolt was chosen as it offered significant benefits including, fast installation, high strength capacity, and a wide range of independent technical accreditations, which include the CE mark, TÜV and ICC-ES Seismic approvals.

The conductor units were winched into position from the scaffolding below and straps used to temporarily position the units in the correct location. Hexagonal head Hollo-Bolts with a Hot Dip Galvanised finish were installed along with a washer to make the connection between the base frame and conductor units. Installation was quick and easy as each bolt was simply inserted into the predrilled slotted holes and once aligned correctly, they were tightened with a wrench to the recommended tightening torque to provide the necessary clamping force. To complete the installation, additional shear pins were installed.

The specification of Hollo-Bolts provided a simple and secure connection solution and one that was adjustable which avoided any additional modifications onsite which could have caused delays with the installation. At nearly twice the height of the London Eye, Ain Dubai opened to the public in October 2021 and offers a majestic new perspective of Dubai’s skyline.

- Simple connection solution

- High tensile and shear capacities

- HDG finish for high corrosion protection

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2024. All rights reserved.