Lindapter Girder Clamps provided a solution for upgrading car production lines.

Location: Ingolstadt, Bavaria, Germany

Market: Automotive

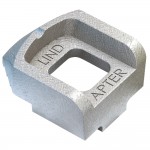

Product: Type A, B & AF Girder Clamps

Client: Audi AG

Audi has been building cars at the Ingolstadt headquarters for more than 70 years. The site continues to develop into a networked digital factory with modern production systems and high-tech solutions enabling highly efficient, sustainable manufacturing. The plant is also getting ready for electric mobility, with measures to increase flexibility laying the foundation for the cars of the future.

In the past maintenance engineers had used a range of self-made and other manufacturers clamps when carrying out modifications to the car production lines. The engineers found that they had to spend a lot of time inspecting and tightening the clamps due to them loosening and twisting with vibrations and dynamic loads caused by the production lines. To reduce maintenance time the responsible engineer wanted to specify clamps that were approved for dynamic applications and compatible with locking washers. They also wanted to strengthen the existing connection points throughout the factory and install additional steel supports.

The engineer contacted Lindapter’s technical support team who provided assistance including connection drawings, technical advice and product testing. Solutions were proposed and accepted for several applications within the factory including:

Overhead Conveyor System: 2-bolt connection for “L” shaped hanger brackets to be connected to overhead steelwork that carry the car conveyor system.

Supporting Steelwork: 4-bolt connection for securing various sized vertical posts with end plates to existing steelwork to provide extra support.

Strengthening Steelwork: 8-bolt connection with location plate and beams joining together end to end, and at 90° to reinforce existing steel above.

Other solutions included connections for beams at a 3° tilt, bracketry to accommodate height changes between two beams, and innovative shaped location plates for connecting nonaligned steel. Each solution incorporated Lindapter Type A, Type B or Type AF Girder Clamps that have independent ETA / CE Mark approval for use in dynamic loading applications.

The maintenance engineers replaced all the existing non-Lindapter clamps and installed additional steel supports using over 5,000 Lindapter Type A & B Girder Clamps in various sizes (M12, M16 and M20) and over 500 Type AF Girder Clamps in size M16. The assemblies used grade 8.8 bolts installed through a range of pre-drilled bracket and end plate arrangements. The clamps with locking washers were quick and easy to install using simple hand tools and calibrated torque wrench, the clamps also had an anti-rotational design that prevented them from rotating during installation.

Lindapter Girder Clamps provided a connection solution independently approved for dynamic load applications. The clamped assemblies are fully adjustable which gave the engineers the ability during installation to manoeuvre them into their final positions before fully tightening the bolts. Installation was quick, minimising interruption to production and downtime, whilst the connections can be easily disassembled in the future if the production line requires further modification.

- Approved for dynamic load applications

- Fully adjustable for easy installation

- Minimises downtime

- Easily disassembled for future upgrades

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2024. All rights reserved.